Electrical equipment is susceptible to reduced insulation performance and structural defects due to various factors, leading to corona and partial discharge phenomena. Electrical discharge poses a significant threat to the power system and is difficult to detect visually. To ensure the safety of power grid operation, it is crucial to detect corona discharge promptly, especially in its early stages.

During the discharge process, electrons in the air continuously gain and release energy. When electrons release energy (during discharge), they emit ultraviolet radiation.

The ultraviolet imager receives ultraviolet signals generated during electrical discharge, processes them into an image, and superimposes them onto a visible light image. This image is then displayed on the imager's screen, allowing technicians to visually identify the location and intensity of the corona discharge and thus assess the insulation condition of the operating equipment.

The ULIRVISION TD100 ultraviolet imager is a portable, handheld device for easy detection of electrical discharges. It determines the magnitude and severity of discharges by measuring the number of photons emitted, and can be used to diagnose, detect, record, and display specific discharge points.

Product Features:

High UV sensitivity reaching 2.2 × 10⁻¹⁸ watt/cm²

Low noise interference, using a completely solar-blind detector

Accurate superposition of UV and visible light across the entire spectrum for precise positioning

Handheld detection for easy operation

Simultaneous focusing of UV and visible light

SD card online upgrade function

High integration and low power consumption

Small size and light weight (1.4 kg) for convenient operation

Professional report analysis software for better on-site situation analysis

The TD100 utilizes full daylight-blind technology, offering high sensitivity, accurate discharge localization, and strong anti-interference capabilities. It is completely unaffected by sunlight and can operate 24/7. Its compact and lightweight design, coupled with simple operation, greatly satisfies users' needs for practicality and convenience. Equipped with professional analysis and reporting software, it is an essential tool for preventive maintenance in substations and high-voltage transmission lines.

The TD100 ultraviolet imager boasts advantages such as immunity to sunlight interference, high sensitivity, accurate identification, and a low false alarm rate. It can detect electrical discharge locations immediately, allowing for the early detection and control of potential hazards, which is of great significance for the safe operation of the power grid.

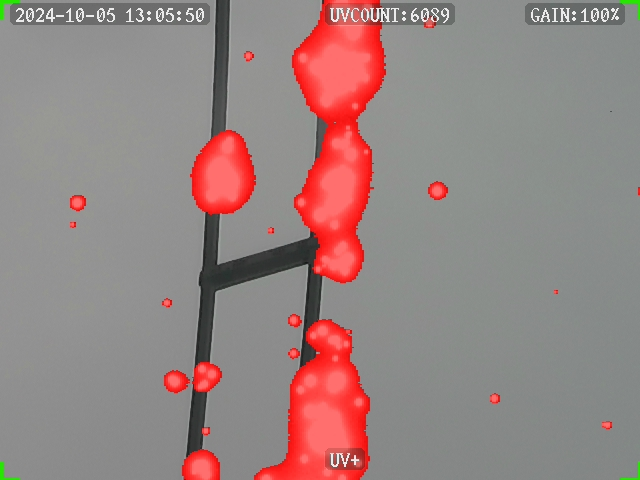

I. Discharge due to conductor contamination

As a crucial component of high-voltage overhead power lines, insulators primarily serve the function of insulation and support. However, during long-term operation, due to the continuous deterioration of the natural environment, insulators can experience surface contamination such as dirt, degradation, moisture absorption, and damage. Under contaminated conditions, the discharge phenomenon between high-voltage conductors and the insulator surface increases significantly.

Dust, salt, or other pollutants on the conductor surface can also lead to electric field distortion and the formation of discharge channels. If the humidity is high, the conductive properties of the contaminated particles increase after absorbing moisture, making the discharge phenomenon even more pronounced, posing a significant risk to the operation of the power system.

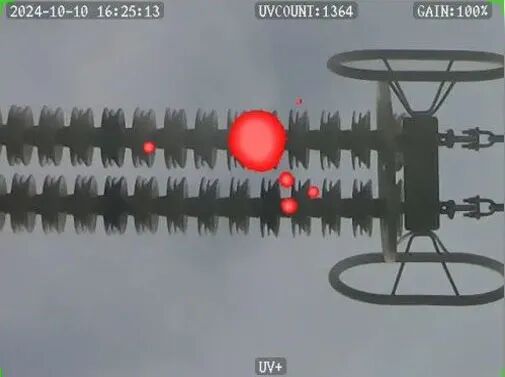

II. Discharge of low-resistance insulators

When the insulation resistance drops to 10–300 MΩ, it is called a "low-value insulator." When the insulation performance of an insulator deteriorates due to internal material defects, external cracking, or aging, the insulation resistance decreases, increasing the risk of discharge and leading to corona, flashover, or arcing. Ultraviolet imaging instruments can directly detect the discharge process, offering advantages such as intuitive observation, good predictability, long observation distance, and safety, thus maximizing the prevention of potential hazards such as insulation breakdown.

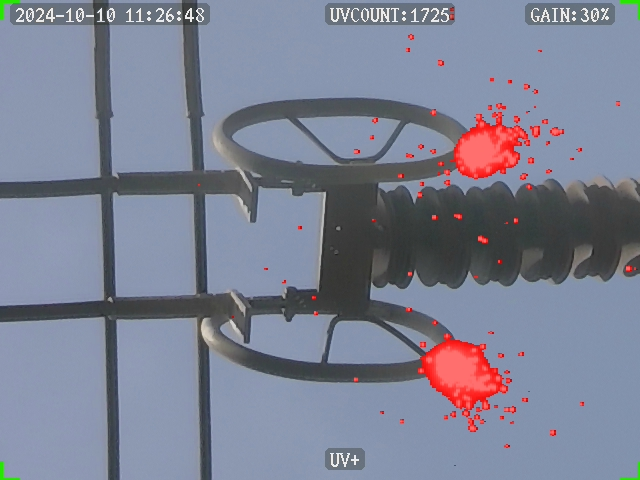

III. Equipotential ring discharge

Grading rings are important components in transmission lines used to equalize electric field distribution. The quality of their design, installation, and maintenance directly affects the stable operation of the power grid. Defects in the design of the grading ring components, burrs and scratches generated during manufacturing and transportation, dimensional mismatches, and frequent rainfall can all lead to discharge problems.

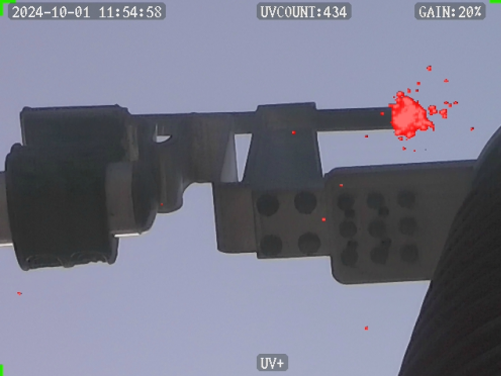

IV. Metal tip discharge

Metal tips are frequent discharge areas during the operation of power transmission and transformation equipment, typically manifesting as a corona discharge and buzzing sound around the metal tip. Especially at locations with a small radius of curvature, the electric field strength is significantly enhanced, easily reaching the breakdown strength of air, thus triggering corona discharge and electrical discharge.

The TD100 ultraviolet imager is suitable for a variety of scenarios requiring discharge detection, providing reliable support for preventive maintenance work in power systems.