In the face of a 'cliff-like' temperature drop, the outdoors has entered an icy mode, yet indoor heating brings us back to life in a second. To ensure safe heating, HVAC inspection is indispensable. Is the floor heating and radiator operating normally? Are there any damages or leaks? How should we detect them? Infrared thermal imagers play a crucial role in ensuring a warm winter.

All objects above absolute zero (-273℃) emit infrared radiation.

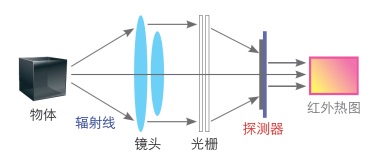

Infrared thermal imagers utilize an infrared detector and an optical imaging objective to receive the infrared radiation energy distribution pattern of the target object. This pattern is reflected onto the photosensitive element of the infrared detector. The incoming infrared radiation is then converted into electrical signals, which are further processed into a visible image – an infrared thermal image. Currently, this is the only diagnostic technology that can instantly visualize and validate thermal information.

Precision Positioning

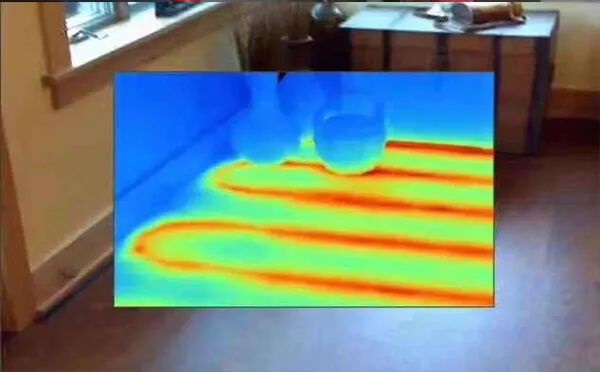

Water Pipe Blockage:A blocked water pipe can disrupt the normal circulation of hot water, leading to a reduction in the heating efficiency of the underfloor heating system. This, in turn, requires more energy consumption to maintain indoor temperatures, thereby increasing energy costs. As a non-destructive inspection tool that visualizes temperature data, an infrared thermal imager can visually display the heat distribution on the floor. It provides a clear view of the temperature of the pipes conducting heat to the floor. In the presence of abnormal temperature increases, it can quickly and accurately locate the blocked area, enabling prompt repairs to prevent circulation issues.

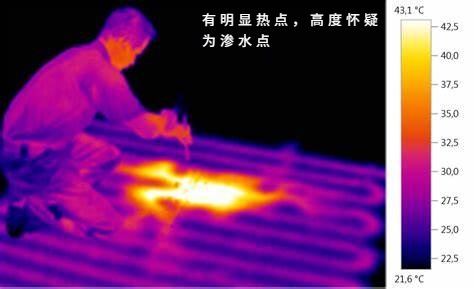

Leak Point Localization:Due to the higher temperature of the warm water pipes beneath the floor and the lower surface temperature, the heat released by the high-temperature warm water pipes can conduct to the surface. It is crucial to monitor changes in the entire high-temperature area of the underfloor heating system. If the area of this high-temperature zone gradually expands, and simultaneously, a gradual decrease in pipeline pressure is observed, it indicates a typical water leakage phenomenon.

Heating Effect Inspection

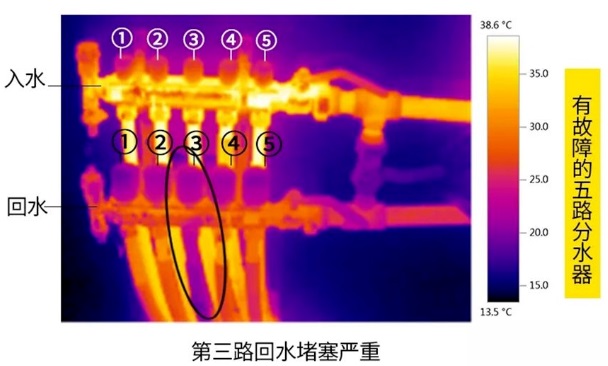

Manifold Malfunction: A malfunctioning manifold can affect the heating effect. Using an infrared thermal imager allows for the quick identification of a faulty manifold, assisting technicians in performing repair work.

Building Envelope

Building Envelope

Tightness Inspection: Infrared thermal imaging equipment can be used to detect thermal energy losses in the heating system. These losses may originate from various parts of the building, such as windows, doors, roofs, and walls. Through the use of an infrared thermal imager, defective areas can be quickly identified. Repairing these areas enhances the insulation effect inside the house, reducing energy waste.

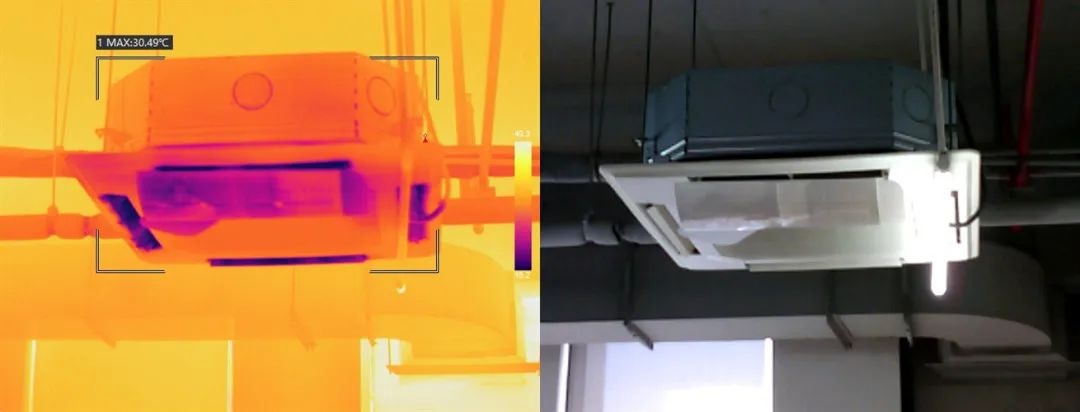

Electrical Equipment Inspection: In addition to underfloor heating, people in the southern regions often choose air conditioners, oil heaters, and other heating devices, leading to a peak in electricity consumption and an increased risk of electrical fires.

During operation, electrical equipment may experience situations such as current overload, poor contacts, and local faults, all of which can result in localized temperature increases. By monitoring the temperature distribution of electrical equipment and circuits, an infrared thermal imager can help identify these abnormal hotspots. Timely repairs can then be conducted to prevent accidents and reduce energy consumption.

For Maintenance Technicians

Identifying areas with temperature anomalies using an infrared thermal imager enables quick and accurate troubleshooting, reducing the workload for technicians and significantly enhancing work efficiency.

For Property Owners

Unlike traditional inspections that require blindly breaking through and damaging the structural integrity of the building, an infrared thermal imager allows for non-destructive testing. This minimizes repair costs and the affected area, reducing economic losses.

Infrared Intelligent Inspection Thermal Imager T5|T6

ULIRVISION Technology's T5|T6 Infrared Thermal Imager features a 384×288|640×480 high-pixel uncooled amorphous silicon microbolometer detector, ensuring precise temperature measurement and delivering excellent imaging quality. Paired with an integrated lens designed in accordance with ergonomics, it effectively enhances detection efficiency.

Portable Infrared Thermal Imager T10

ULIRVISION Technology's T10 Infrared Thermal Imager is a portable infrared thermal imaging device. It features precise temperature measurement, real-time imaging, and automatic high-temperature tracking, enabling rapid target acquisition. Integrated with various sensing functions, including infrared, visible light, supplementary lighting, and laser indication, it combines reliable performance with a compact and lightweight design, making it suitable for daily inspection and easy portability.