Safety accidents are the Damocles sword hanging over steel companies, and gas leaks are the focus of safety accident management. In the process of steel production, blast furnaces, converters, and coke ovens generate a large amount of gas, including a large amount of carbon monoxideCO.

In the process of gas recovery, purification, and utilization, there are many facilities and equipment, wide distribution of pipelines, and frequent operations, which increase the risk factors. CO gas leaks are not only harmful to the environment but also a potential danger to human life. So, how to prevent CO gas leaks?

Pipeline

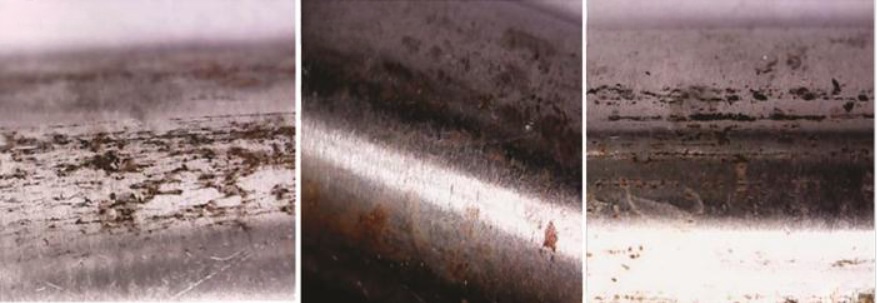

Gas pipelines, often made of carbon steel, face the challenge of high concentrations of suspended solids. These solids accumulate in the pipeline, forming porous deposits that lead to localized corrosion perforations due to the concentration difference cell corrosion around the surrounding metal. This corrosion can result in gas leaks.

Blast Furnace

In the process of dust removal and cleaning with seawater, chlorine ions stripped from raw ore materials possess penetrative and corrosive properties. This can lead to localized corrosion at the bottom or corners of pipelines, causing gas leaks.

Gas Cabinet

Gas cabinets, steel containers used for storing industrial and domestic gas, can experience gas leaks due to inadequate processing, damaged rubber seals, incomplete corrosion prevention, and other reasons.

Due to the colorless and odorless nature of CO gas, with a density close to that of air, slow leaks can be easily masked by changes in airflow, especially in densely piped areas. Traditional detection methods often fail to comprehensively cover such scenarios. To address gas leak issues effectively, the Optical Gas Imaging Thermal Imager becomes a primary choice.

This imaging tool visualizes CO gas leaks from a safe distance, rapidly scanning large areas. Whether in pipelines or equipment, it provides real-time imaging of even the slightest leaks, eliminating the need to shut down systems or halt operations for inspection. With this optical gas imaging technology, it not only enhances work efficiency but also ensures the safety of personnel.

CO Optical Gas Imaging Thermal Imager — G460

Developed specifically for CO gas using optical gas imaging technology, the ULIRVISION Technology G460 offers optical visualization of gas leaks from a considerable distance. G460 is applicable to various stages of steel manufacturing, effectively detecting even minor leaks. The high sensitivity mode of G460 achieves optimal image contrast for detecting the lowest levels of gas emissions.

Switching the G460 gas detection from normal mode to high sensitivity mode leaves no room for even the smallest gas leaks.

G460 Product Advantages

Refrigerated high-sensitivity detector, sensitivity ≤12mk

CO gas detection sensitivity ≤2.2g/hr (CO)

High-sensitivity mode can detect minor gas leaks

Capable of CO gas imaging for leak detection and infrared temperature measurement

Images and videos can be directly stored on an SD card

Compact size, weighing only 2.8kg

Intelligent operation

Visible Light Images

CO Gas Leak in Steel Pipeline

Gas Detection Mode

Even in the face of minor gas leaks, G460 leaves no room for oversight.

Steel production facilities not only include numerous pipelines but also various steelmaking devices, often highlighting issues with leak detection that can lead to irreversible consequences. To streamline inspection work, Leak Detection and Repair (LDAR) technology standardizes a series of steps, perfecting procedures, component detection, leak repair, and closed-loop reporting.

The ULIRVISION Technology G460 incorporates an LDAR system, helping the steel industry simplify shutdown processes and procedures, saving significant capital for companies. By pre-setting inspection areas and ranges, uploading real-time detection data, and generating reports with a single click, it greatly reduces the risk of leaks and errors, minimizing losses from gas leaks.